Year 4 English Comprehension: A Comprehensive Guide

Year 4 comprehension PDFs offer focused practice, building skills through structured texts like those about outer space, enhancing reading abilities and analytical thinking.

What is Year 4 English Comprehension?

Year 4 English comprehension centers on a child’s ability to understand and interpret written text, moving beyond simply decoding words. PDF worksheets play a crucial role, providing targeted practice with varied texts. These resources often feature passages, followed by questions designed to assess understanding at different levels.

Specifically, Year 4 comprehension PDFs frequently focus on non-fiction texts, like the example provided about outer space. This helps children learn to extract information, identify key features, and understand how non-fiction texts are structured. The goal is to foster active reading habits and build a solid foundation for future literacy success, utilizing structured activities.

The Importance of Comprehension Skills in Year 4

Strong comprehension skills in Year 4 are foundational for success across all subjects, not just English. Year 4 English comprehension PDFs directly support this development by providing focused practice. Understanding what is read allows children to learn effectively, participate confidently in class, and develop a lifelong love of reading.

These PDF worksheets help pupils move beyond decoding to truly understanding the meaning behind the words. Working with texts, such as those about outer space, encourages active reading and critical thinking. Developing these skills now prepares them for more complex texts and challenges in later years, building a strong academic base.

Key Reading Skills for Year 4

Essential reading skills for Year 4 pupils include decoding, fluency, vocabulary development, and comprehension. Year 4 English comprehension PDFs are invaluable tools for honing these abilities. Worksheets often present structured texts, like those exploring outer space, to practice identifying key information.

These resources help children learn to extract meaning, make inferences, and understand the author’s purpose. PDFs provide targeted practice in areas where students may struggle, reinforcing skills through repetition and varied question types. Regular use of these materials builds confidence and fosters a deeper appreciation for reading.

Decoding and Fluency

Decoding, the ability to accurately and rapidly read words, is foundational for Year 4 English comprehension. PDF worksheets can support this by providing texts with appropriately challenging vocabulary and sentence structures. Practicing with these materials builds fluency – reading smoothly, accurately, and with expression.

Repeated exposure to text through comprehension PDFs helps children recognize common words and patterns, reducing cognitive load and freeing up mental energy for understanding. Texts, such as those about outer space, offer engaging content. Consistent practice with these resources improves reading speed and accuracy, ultimately enhancing overall comprehension skills.

Vocabulary Development

Year 4 English comprehension PDFs are excellent tools for expanding a child’s vocabulary. Exposure to new words within context, like in texts about outer space, is crucial for understanding. These worksheets often include activities that encourage children to define unfamiliar terms and use them in sentences.

A richer vocabulary directly impacts reading comprehension. PDF resources can present words in varied ways, reinforcing learning. By encountering new vocabulary repeatedly, children build confidence and improve their ability to understand complex texts. This, in turn, fosters a love of reading and a stronger grasp of the English language.

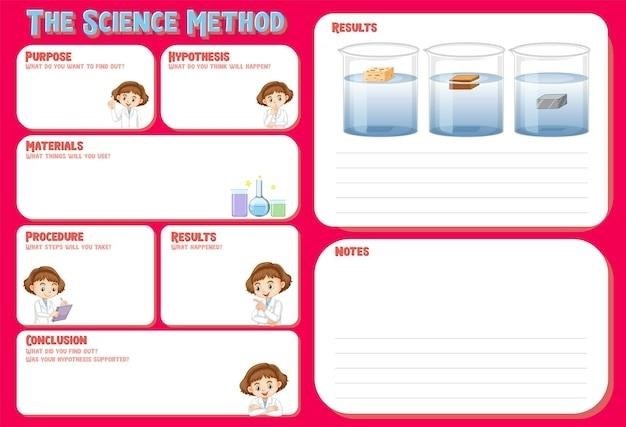

Types of Comprehension Questions in Year 4

Year 4 English comprehension PDFs frequently utilize diverse question types to assess understanding. These often include retrieval questions, asking pupils to find specific information directly from the text, like facts about outer space.

PDF worksheets also incorporate inferential questions, requiring children to ‘read between the lines’ and draw conclusions. Vocabulary-in-context questions test understanding of word meanings as used within the passage. Practicing these question types through PDF resources prepares pupils for standardized assessments and builds critical thinking skills.

Literal Questions (Retrieval)

Year 4 English comprehension PDFs heavily feature literal, or retrieval, questions. These questions directly test a child’s ability to locate explicitly stated information within the text. For example, a PDF about outer space might ask, “What is the name of the planet closest to the sun?”

These questions require no inference; the answer is present in the text. Mastering retrieval is foundational. PDF worksheets provide ample practice, strengthening this skill. Successfully answering these builds confidence and prepares pupils for tackling more complex question types found in comprehension exercises.

Inferential Questions

Year 4 English comprehension PDFs progressively introduce inferential questions, demanding more than simple retrieval. These require pupils to ‘read between the lines’ and draw conclusions based on clues within the text. A PDF passage about a character might ask, “How do you think the character is feeling?” – the answer isn’t directly stated.

Developing this skill is crucial. PDF worksheets often include prompts encouraging children to justify their answers with evidence from the text. This fosters critical thinking and analytical skills. Successfully navigating inferential questions demonstrates a deeper understanding of the material presented within the comprehension PDF.

Vocabulary in Context

Year 4 English comprehension PDFs frequently assess vocabulary understanding within the text, not just definitions. Pupils encounter unfamiliar words and must deduce meaning from surrounding sentences – ‘vocabulary in context’. A PDF might present a passage and ask, “What does ‘astonished’ mean in this sentence?”

These PDF exercises move beyond rote memorization, encouraging children to become active readers. Worksheets often provide multiple-choice options, requiring careful consideration of how the word functions in the passage. Mastering this skill is vital for expanding vocabulary and improving overall reading comprehension, as demonstrated through successful PDF completion.

Non-Fiction Comprehension for Year 4

Year 4 English comprehension PDFs often feature non-fiction texts, like articles about outer space, to build skills in extracting factual information. These PDF worksheets emphasize identifying key details and understanding how information is presented. Pupils learn to navigate text structures, such as headings and subheadings, to locate answers efficiently.

A typical PDF exercise might ask students to identify the main purpose of a paragraph or summarize a section in their own words. These activities develop critical thinking and the ability to discern important information, skills crucial for academic success and utilizing PDF resources effectively.

Identifying Text Structure (e.g., headings, subheadings)

Year 4 English comprehension PDFs frequently focus on teaching children to recognize how non-fiction texts are organized. Worksheets often include passages, such as those detailing outer space, with clear headings and subheadings. Pupils learn these elements aren’t just decorative; they signal the main ideas within sections.

Exercises within these PDF resources ask students to identify the purpose of each heading or subheading, and how they relate to the overall topic. Understanding this structure helps children quickly locate specific information and improves their overall reading comprehension, making PDF usage more efficient;

Understanding Non-Fiction Features (e.g., captions, diagrams)

Year 4 English comprehension PDFs often incorporate non-fiction texts rich with features like captions and diagrams. These aren’t simply visual additions; they provide crucial supplementary information. Worksheets centered around topics like outer space, for example, will include images with descriptive captions, prompting students to analyze their relevance.

PDF exercises encourage pupils to interpret diagrams, explaining what they illustrate and how they connect to the main text. Recognizing the purpose of these features – to clarify, support, or expand upon the written content – is a key comprehension skill. Mastering this enhances understanding and analytical abilities.

Fact vs. Opinion

Year 4 English comprehension PDFs frequently assess a student’s ability to differentiate between factual statements and subjective opinions within non-fiction texts. Exercises often utilize passages, such as those detailing outer space, presenting information alongside viewpoints. Pupils learn to identify statements verifiable with evidence – facts – versus beliefs or judgments – opinions.

PDF worksheets guide children to recognize signal words indicating opinion (“I think,” “best,” “most”). This skill is vital for critical thinking, enabling students to evaluate information objectively. Understanding this distinction builds analytical skills and prepares them for discerning reliable sources.

Fiction Comprehension for Year 4

Year 4 English comprehension PDFs dedicated to fiction often present short stories designed to assess understanding of narrative elements. These worksheets frequently focus on key areas like character development, plot progression, and setting descriptions. PDF exercises encourage pupils to analyze how characters change, identify the sequence of events, and visualize the story’s environment.

Worksheets may include questions prompting students to infer character motivations or predict outcomes. Utilizing these resources helps build crucial skills in imaginative thinking and textual analysis. They provide structured practice for interpreting fictional narratives and enhancing overall reading comprehension.

Character Development

Year 4 English comprehension PDFs often include exercises specifically targeting character development within fictional texts. These worksheets prompt pupils to analyze how characters are portrayed through their actions, dialogue, and thoughts. Questions frequently ask students to identify character traits, explain motivations, and trace changes a character undergoes throughout a story.

PDF resources may present scenarios requiring pupils to infer a character’s feelings or predict their reactions. This focused practice strengthens analytical skills and encourages deeper engagement with the narrative. Understanding character development is crucial for building empathy and interpreting complex storylines.

Plot and Setting

Year 4 English comprehension PDFs frequently feature passages designed to assess understanding of plot and setting. Worksheets often present short stories or excerpts, followed by questions that require pupils to identify the main events in sequence – the plot. They also ask students to describe the time and place where a story occurs – the setting – and explain how the setting influences the narrative.

PDF exercises may include tasks like mapping story events or analyzing how changes in setting impact character actions. These resources help pupils recognize the interconnectedness of plot and setting, enhancing their overall comprehension skills and analytical abilities.

Identifying the Main Idea

Year 4 English comprehension PDFs commonly include exercises focused on pinpointing the central thought or message within a text – identifying the main idea. These worksheets present passages, often non-fiction like texts about outer space, followed by multiple-choice or open-ended questions. Pupils must determine the overarching point the author is trying to convey.

PDF resources often require students to differentiate between the main idea and supporting details. Activities may involve summarizing paragraphs or selecting the sentence that best encapsulates the text’s core message, strengthening analytical skills and reading comprehension.

Utilizing Year 4 English Comprehension PDFs

Year 4 English comprehension PDFs are invaluable tools for reinforcing reading skills. They provide targeted practice, often featuring diverse text types – from fictional stories to non-fiction passages about subjects like outer space. PDF worksheets allow for flexible learning, enabling independent study, homework assignments, or classroom activities.

These resources frequently include a range of question types, assessing literal understanding, inferential skills, and vocabulary knowledge. Utilizing PDFs allows educators to easily track student progress and identify areas needing further support, fostering a stronger foundation in reading comprehension.

Benefits of Using PDF Worksheets

Year 4 English comprehension PDF worksheets offer numerous advantages for both students and teachers. They provide a cost-effective and readily accessible resource for practicing essential reading skills. The structured format of PDFs helps pupils focus on specific comprehension techniques, like identifying key information in texts about outer space.

PDFs facilitate independent learning and allow for repeated practice without resource depletion. They are easily printable, making them ideal for classroom use or home learning. Furthermore, PDF worksheets often include answer keys, enabling self-assessment and promoting student autonomy in their learning journey.

Finding Reliable PDF Resources Online

Locating trustworthy Year 4 English comprehension PDF resources requires careful consideration. Educational websites maintained by schools or established publishing houses are excellent starting points. Websites offering free worksheets should be vetted for accuracy and age-appropriateness, ensuring content aligns with the Year 4 curriculum.

Teacher-created resource platforms, like TES, often host high-quality PDF materials. Always preview the worksheet before use to confirm it suits your pupils’ needs. Look for resources that include diverse text types, such as non-fiction passages about topics like outer space, and varied question formats to comprehensively assess comprehension skills.

Strategies for Improving Comprehension

Utilizing Year 4 English comprehension PDF worksheets effectively requires employing active reading techniques. Encourage pupils to preview texts before reading, discussing potential topics and vocabulary. Pre-reading activities, like brainstorming or questioning, activate prior knowledge and enhance engagement.

During reading, prompt children to highlight key information or make notes. Post-reading discussion is crucial; ask questions that require pupils to recall details, infer meaning, and analyze the text. Regularly using varied PDF resources, including fiction and non-fiction, builds a broader skillset.

Active Reading Techniques

Employing active reading with Year 4 English comprehension PDF worksheets transforms pupils from passive receivers to engaged thinkers. Encourage highlighting key details within the text, prompting focused attention. Asking questions before, during, and after reading fosters deeper understanding.

Summarizing paragraphs in their own words solidifies comprehension. Utilizing graphic organizers, like story maps or fact webs, helps visualize information. Regularly using varied PDF exercises, such as those focusing on outer space, builds confidence and skill. These techniques empower children to become independent, analytical readers.

Pre-Reading Activities

Before diving into a Year 4 English comprehension PDF, activate prior knowledge! Discuss the topic – for example, outer space – brainstorming what pupils already know. Examining illustrations and headings provides valuable clues about the text’s content.

Predicting what the text might be about sparks curiosity and sets a purpose for reading. Introducing key vocabulary beforehand, using a word bank related to the PDF’s theme, reduces frustration. These activities prepare young minds, making comprehension more accessible and enjoyable, ultimately maximizing learning from the worksheet.

Post-Reading Discussion

Following completion of a Year 4 English comprehension PDF, engage pupils in thoughtful discussion. Encourage them to share their answers and explain their reasoning, fostering critical thinking skills.

Ask open-ended questions about the text, prompting them to elaborate on character motivations or the main idea. Review challenging vocabulary encountered within the PDF, ensuring understanding. Discuss any difficulties faced during the activity, offering support and clarification. This collaborative approach solidifies comprehension and builds confidence, maximizing the benefits of the worksheet.